The use of metallic labels in IML (in-mold-labeling) is a growing trend that reaches practically all consumer sectors, since with its use you can get a premium finish that will allow you to better differentiate from your competitors. Nevertheless, finish effects are not the only advantage that metallic labels present. Among many, we can name the following:

- Long-lasting quality: the hardness provided by the metal makes the shapes more durable. A highly-valued feature for those shapes with a long-lasting life such as bins or plastic crates and drawers.

- Price: Part manufacturing costs through IML-injection are significantly lower than directly applying metal layers.

- Rust: IML metallic labels do not present rust issues.

- Part physical integrity: Common bumps and gaps between metal thin layers, both are avoided by using IML metallic labels.

Summing up, with IML metallic labels we get a better product finish, more economical, and a longer shelf-life.

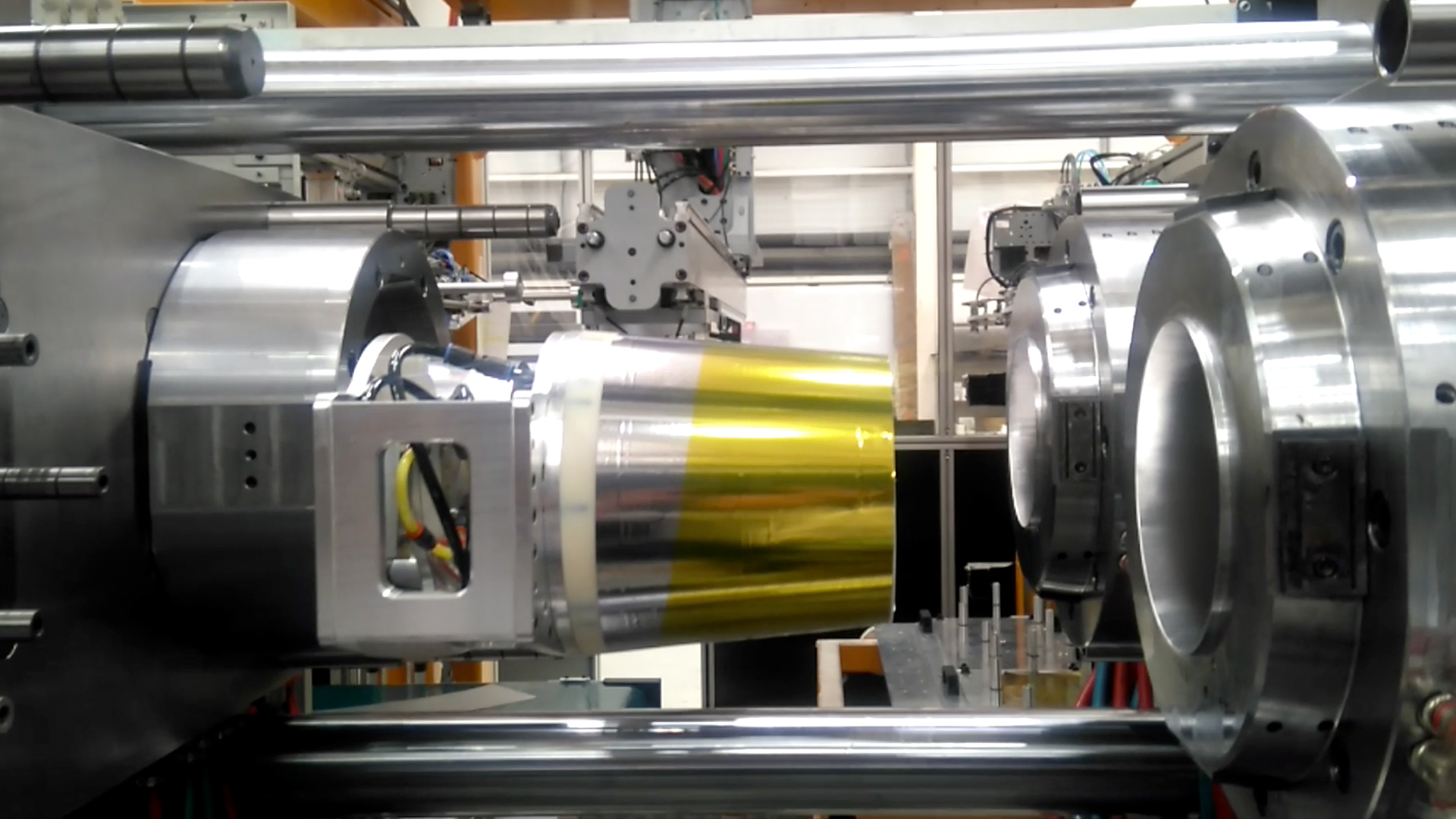

However, IML metallic labels handling differs from the usual PP labels, and therefore, some injectors suffer problems when manufacturing the parts. IML Solutions has developed an innovative system that makes it easier for them to work with this type of labels. Its main advantages are the compatibility with traditional labels (the same robot can be used for both metallic and PP labels), and the possibility to adapt it to the existing moulds that the client owns. With this system, you do not need to worry about anything while you enjoy all the advantages of metallic labels. Reach an all-the-time optimised and controlled production thanks to IML Solutions’ experts.

Further information in the following video::